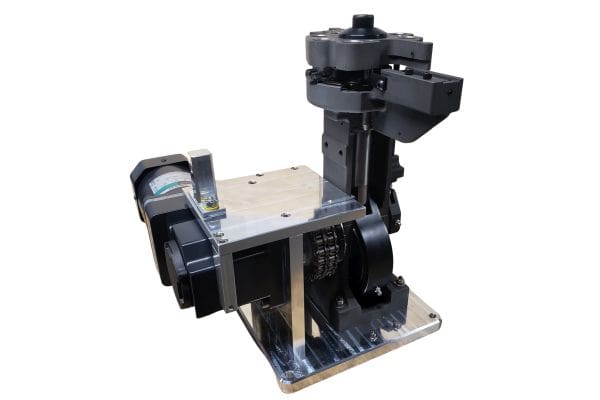

THE FAST AND FRIENDLY BRASS AUTO-DRIVE SOLUTION FOR THE DILLON RL1100

The Permanent Solution to Speeding Up Your Ammo Production

Farmington, MO – Fast and Friendly Brass, a premier brand in tooling and processing equipment and supplies for optimal efficiency in brass loading and reloading, has the permanent solution for adding an Auto Drive to your Dillon RL 1100.

“We have produced the best solution for adding an Auto-Drive to the Dillon Precision RL 1100 Reloader,” said Bill Birmingham, Owner of Fast and Friendly Brass. “You have to send us your press, and we’ll send it back with the ultimate solution for automating the process. It is a permanent solution, but trust me when I say that it is well worth it.”

Like other Fast & Friendly Brass Auto-Drives, the RL 1000 Auto-Drive is made in the U.S. using 6061-T6 billet aluminum and hardened 4140 billet steel. It works for the full stroke of the stock Dillon RL 1100 and has a direct drive with no belts or chains. The Auto Drive runs on a VFD (Variable Frequency Drive) controlled 1/4HP motor that runs on standard 110/120 VAC and is rated for well over 10,000 hours of service. The kicker with the Fast and Friendly Brass auto-drive is that it is crankshaft driven, running continuously in one direction. This means it runs smoother and more efficiently. Competing drives waste time and energy by using a back and forth motion.

You can select from a 36:1 gear ratio, with speeds of 0-5333 for all pistol brass and easy-to-size rifle brass, but not for a .300 Blackout conversion. The 50:1 gear ratio has speeds of 0-3840 for most general applications. There is an available 75:1 gear ratio with speeds of 0-2560 for really tough-to-size .30 cal brass, like that is typically shot out of belt-fed full auto, or SCAR rifles. Depending upon your needs, these options should cover you. For more information, go to the Fast &Friendly Brass website.

About Fast and Friendly Brass

Fast and Friendly Brass is owned in whole by Bill Birmingham of Farmington, MO. The company started out processing and selling brass in the St. Louis area starting in 2012 and nationally in 2014. In late 2015 Fast and Friendly Brass stopped processing brass to focus on a bigger need in the market – better tooling and equipment to improve the efficiency of reloading and brass processing. Since then, the company has become an industry leader in high-quality products to make reloading more precise and efficient. Learn more at fastandfriendlybrass.com.